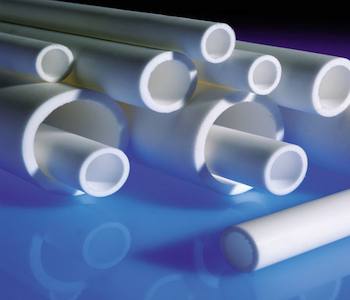

Uncover the Potential of Porex’s Porous Plastic Tubes

Porex offers an extensive range of porous plastic tubes in a variety of diameters, lengths, and pore sizes. Ideal for filtration, diffusion, or venting applications, these products are available in both standard and custom options, ensuring we can meet your precise specifications.

Our sintered polyethylene tubes cater to a wide array of industrial applications and offer excellent strength and chemical resistance. They can be easily processed to fit your specific needs. This adaptability guarantees that Porex’s porous plastic tubes can meet even the most precise requirements of your projects.

Porous Plastic Tube Options

Porex manufactures sintered polyethylene (PE) and porous fiber tubes in multiple global locations and ships them worldwide. The tables below show various standard options manufactured in Europe and the United States, but all options are available to ship globally.

Conversion and Assembly Options

When it comes to converting our porous plastic tubes, many options are available to suit your specific needs. Porex has A NETWORK OF PREFERRED CONVERTERS equipped to assist with large and small projects. These converters have the expertise to guide you through the conversion process and stock some of our products for added convenience.

| Converting & Assembly Method | Sintered PE | Bonded Fiber |

|---|---|---|

| Die cutting | Yes | Yes |

| Digital knife cutting | Yes | Yes |

| Rotary die cutting | Yes | No |

| Slitting | No | Yes |

| Overmolding/injection molding | No | No |

| Laminating | Yes | Yes |

| Thermal and ultrasonic welding | Yes | Yes |

| Press Fit | Yes | Yes |

| Adhesive bonding | Yes | Yes |

| Compression seal | No | No |

In addition to standard items, products may be customized to meet specific geometrical and performance requirements, including high temperature performance, custom air-flows, custom materials and dimensions.

Related Resources

Porex: The Perfect Fit

Overview of functional solutions that help manufacturers overcome complex product design challenges and bring products to market faster.

Understanding Pore Size Distribution-video

A visual guide to understanding pore size distribution video

*coming soon*

coming soon