Advanced Porous Polymer Material Science Expertise

For over 60 years, Porex has applied our extensive porous polymer material science, product design, and custom plastic manufacturing expertise to developing custom-engineered porous solutions that help you address complex product development challenges and accelerate product launches. With our proprietary porous polymer technologies, we design and produce advanced porous materials exhibiting a broad range of thermal, chemical, and mechanical properties. Our development engineers will find the right technical solution in complex situations with multiple functional requirements using our expansive portfolio of materials and technology platforms.

Different Types of Porous Technologies

Explore the four different types of proprietary porous technology platforms that our engineers leverage to design and manufacture custom porous components for your products.

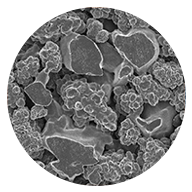

Sintered Porous Plastics

Engineered from various polymers with controlled pore sizes to provide outstanding strength, durability, chemical resistance, resiliency, and design flexibility across multiple applications.

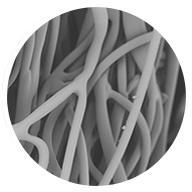

Porous Fiber

Fibers are bonded together to create two-dimensional cross-sections and extruded to create three-dimensional shapes. A blend of polymeric fibers bonded together for ideal fluid handling capillary structures.

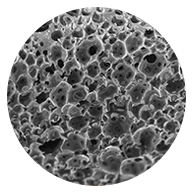

Porous Foam

A two-step pre-polymer process that uses customized blends of raw materials through a clean polyurethane process without the use of catalysts offers a wide range of softness, densities, and porosities.

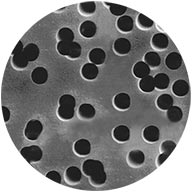

Membranes

Variety of porous membrane solutions that use controlled processes to ensure consistent and repeatable pore structures, including sintered PTFE, Oxyphen track-etched, and PES membranes.

Register for our On-Demand Webinar

Master the Secret Weapon for Product Performance: An Introduction to Porous Polymers

Advanced Porous Materials

The structure and properties of advanced porous materials can be tailored at the molecular or nanoscale level. Their versatility enables engineers to address functional design challenges with precision, leveraging specific material characteristics such as controlled pore size, surface chemistry, and mechanical strength.

Applications for Advanced Porous Materials

Advanced porous materials have emerged as key components in the design and functionality of various medical devices, enhancing their performance and expanding the possibilities in medical technology.

Advanced porous materials play a pivotal role in various water filtration technologies, addressing the need to remove contaminants, impurities, and pollutants from water sources.

The unique properties of advanced porous materials contribute to selective filtration, durability, and adaptive functionality, ensuring that gas sensors deliver reliable and accurate results in diverse and challenging environments.

Why do pore size and flow matter?

Learn more in our new technical article