Sintered PTFE Hydrophobic Membrane Technology

Made from 100% pure PTFE that is free of PFOA, embark on a journey through the versatility of our Porex Virtek® PTFE membrane materials, which include expanded or sintered engineered manufacturing options to fulfill a diverse spectrum of venting demands. Standing out for their exceptional performance, our porous PTFE membranes offer unparalleled advantages across a multitude of applications

To address some of the most demanding medical and industrial applications, our PTFE filter membranes can filter particles as small as 0.1 micron in environments up to 500°F. This waterproof membrane is extremely durable and provides superior chemical resistance to aggressive media and corrosive solvents that can impact device functioning and overall performance.

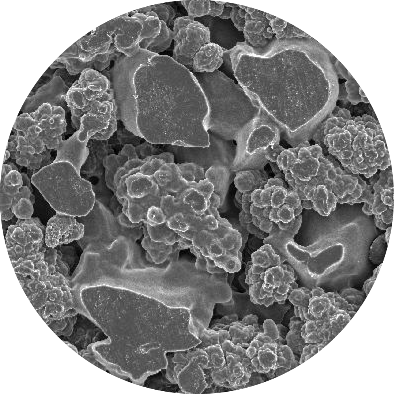

Sintered PTFE Membrane

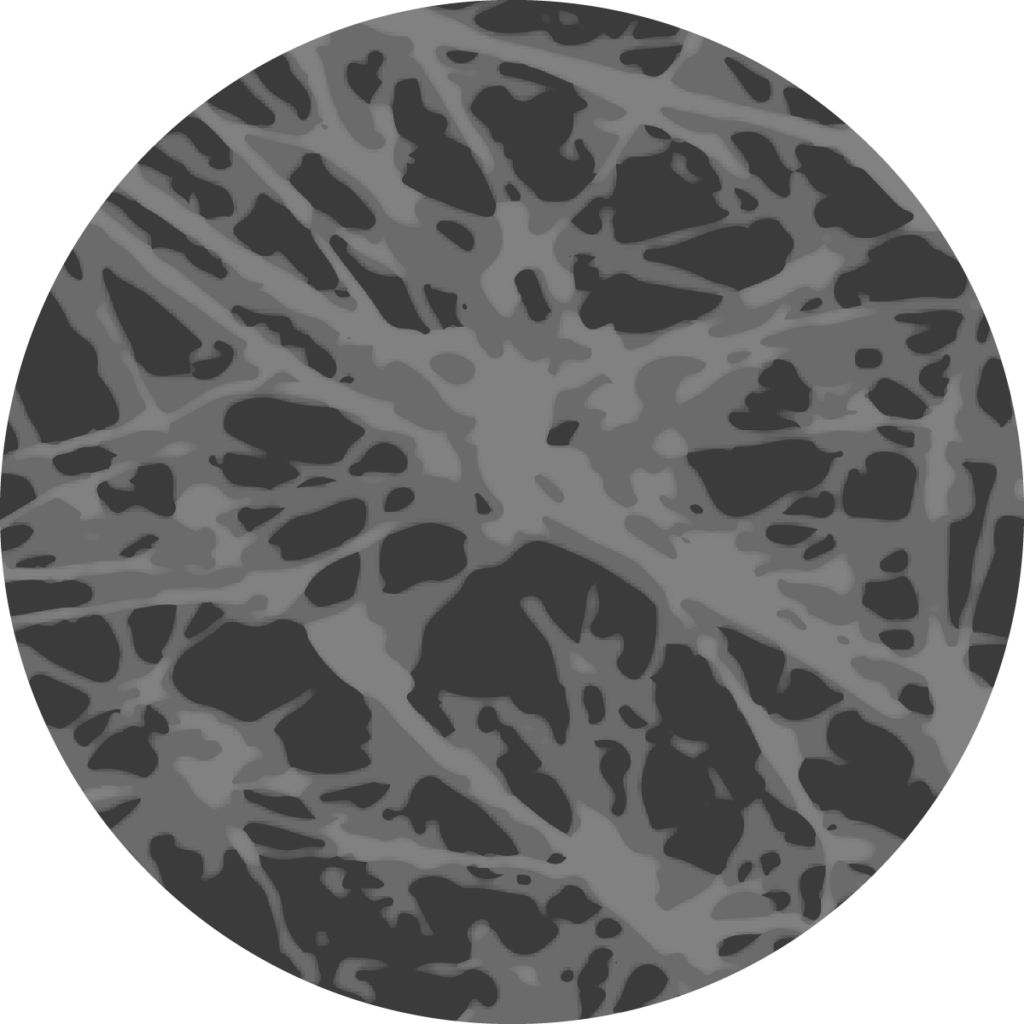

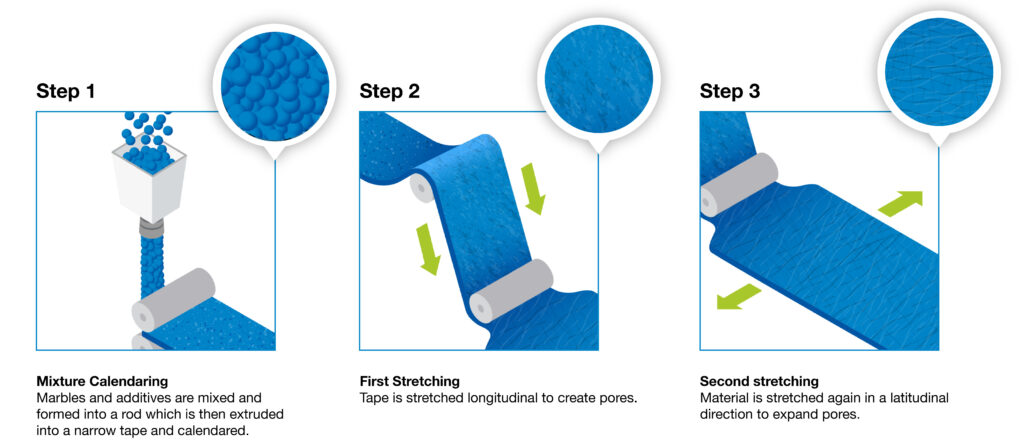

Expanded PTFE Membrane

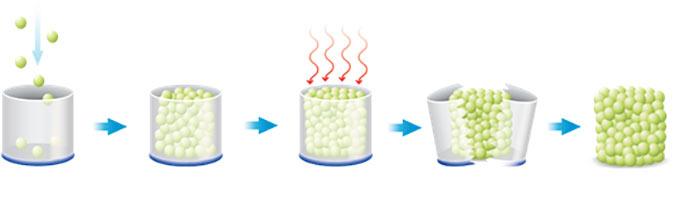

Manufacturing process

Sintered PTFE Membrane

Naturally Robust

Crafted from pure PTFE through a unique sintering process honed over decades using a combination of heat and pressure to bond the materials together. The objective is not to melt or change the main properties of the material – but to create a customized porous material specific to the customer’s needs and applications. the skived membrane film creates a robust porous depth filter – making it the most robust barrier to liquids entering from within or from leaking outside.

Able to be converted into endless formats, as well as surface treatments and printing making it our toughest membrane for demanding environments.

Expanded PTFE (ePTFE) Membrane

Versatility Meets Excellence

Our widest range of airflow and environmental protection properties in venting and filtration. Created by extruding and stretching PTFE under controlled conditions. With an array of supporting base layers, it combines depth and surface filtration to ensure reliability alongside some of the highest airflow and leak-proof

Register for our On-Demand Webinar

Intro to Sintered PTFE Membrane Technology

Options for customizing PTFE membranes

Standard Porex Virtek product offerings

Common applications for PTFE hydrophobic membranes

This list of application examples is just a small selection of what is possible. Check out our Areas of Expertise to explore a specific application.

Vent

This is the most common functionality of Porex Virtek PTFE. From electrical enclosures, container venting, and diagnostics to medical devices and EV battery vents, many applications rely on venting for their product to work properly. Our durable and reliable PTFE vents are a perfect option to support your needs.

Reflect

For UVC disinfection devices where a highly reflective and evenly distributed UVC energy is critical to ensuring proper deactivation of pathogens, our sintered PTFE membrane is an excellent choice.

Filter

When addressing challenges involving cross-contamination, many devices must function as a filter and vent. Our sterilization container filters, which are reusable, are a prime example, as a vent allows pressure equalization during sterilization, and a filter provides a barrier to bacteria during subsequent storage.

Download our Technical Brief

Porosity Analysis on Hydrophobic Microporous Membranes

Related Resources

What Is the Difference Between ePTFE and Sintered PTFE?

Discover the differences between using ePTFE and sintered PTFE in protection and protective vents and which one is the best choice for your application.

Porex Virtek PTFE Fact Sheet

Learn more about the distinctions between sintered Porex Virtek PTFE and ePTFE, enabling you to make informed decisions for your specific applications.

ePTFE Membrane Support Backing Guide

Explore our guide for selecting the support backing material that best fits your specific application.

Porex Membrane Overview Infographic

Find the perfect membrane solution, including selection criteria and material options tailored to navigate

complex venting and filtration challenges effectively.