Track-Etched Membranes Offer More Precise Control Over Pore Size and Pore Density

Our track-etched membrane technology comes to us from our sister company Oxyphen, a global leader in microporous membrane products with quality manufacturing sites in Wetzikon, Switzerland, and Lottsletten, Germany. Working with Oxyphen, Porex can support our customers across many venting and filtration applications in the life science, automotive, industrial, and consumer markets.

Track-etched membranes (TEM) feature a unique pore structure that offers the smallest pore size and pore density tolerances on the market. Due to their smooth surface, track-etched membranes are a perfect surface filter with reversible (backflush) and self-cleaning functionality for hydrophobic, oleophobic, and hydrophilic applications.

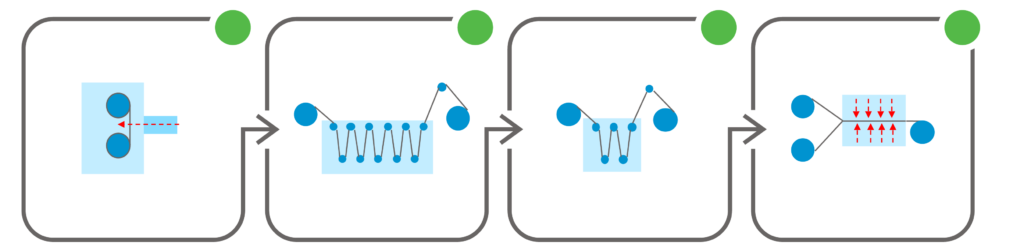

There are two membrane technologies for customers to choose from – Unique-Mem® and RoTrac®. Unique-Mem® track-etched membranes are a single, unlaminated membrane layers that are available as hydrophobic or hydrophilic. Depending on pore density, they can also be transparent or translucent. RoTrac® membranes are laminated Unique-Mem® track-etched membranes that are supported with nonwovens (PP or PET) to create a more robust laminated membrane structure. They, too, are available as either hydrophilic or hydrophobic. All of our track-etched membranes are 100% free of perfluorooctanoic acid (PFOA) and 98% free of PFAS and produced using a 100% controlled two-step process that involves beaming with accelerated noble gas ions and then etching the cylindrical pores along the tracks.

A full spectrum of membrane assembly options is available to our customers, including rollstock, pre-punched discs, self-adhesive pads, pressure compensation units, as well as custom assemblies and modules for specific applications.

Register for our On-Demand Webinar

Intro to Track-Etched Membrane Technology

Manufacturing process

Partnering with our sister company Oxyphen, our track-etched membrane technology is created using a two-step process. Using proprietary beaming equipment operated only by Oxyphen employees, we begin by performing heavy ion beaming of the polymer film. This allows for 100% control of the pore density. Each ion creates a laten track, which we then etch cylindrical pores along. This allows for 100% control of the pore sizes. Optional surface treatments and lamination processes are also available which can expand functionality as well as mechanical stability if it is needed for the application.

Options for customizing track-etched membranes

Common applications for track-etched membranes

This list of application examples is just a small selection of what is possible.

Filter

Our track-etched membranes offer ultra-precise flow control and filtration efficiency. They have been used for many years to support tissue engineering, pharmaceutical research, and IV drug delivery among other filtration applications.

Vent

Whether to relieve pressure, allow for cooling, or protect contents from the external environment, our track-etched membranes and membrane assemblies can help to solve venting challenges in automotive, life science, industrial, and consumer applications.

Why do pore size and flow matter?

Learn more in our new technical article

Related Resources

Membrane Design Guide

Discover how to effectively design a membrane solution to navigate complex venting and filtration challenges.

Oxyphen Track-Etched Membranes

Explore how track-etched membranes are manufactured and the breadth of technology options offering a unique pore structure that offers the smallest pore size and pore density tolerances.

Learn More

OxyDisc Track-Etched Membrane Discs Brochure

Effortlessly assemble pre-punched hydrophobic or hydrophilic Oxyphen track-etched membranes into housings. Learn more about the benefits and available options.

Oxyphen Rollstock Membrane Brochure

Discover the multiple benefits and available options offered by Oxyphen’s rollstock track-etched membrane, the ideal cost-effective solution for high-volume, next-generation products.