Glass Fiber Innovation Expert

Porex glass fiber filtration media offers a versatile solution with a wide range of particle retention sizes and thicknesses. While it is widely recognized for its applications in clinical, life science, and medical products, its utility extends beyond these domains. Serving as effective depth filters, Porex glass fiber media is engineered to handle substantial sample volumes and challenging solutions without encountering premature clogging or compromising flow rates, without the need for binders.

Porex’s commitment to stringent purity standards makes our porous glass fiber media suitable for various applications from life sciences to industrial filters. These applications include but are not limited to spin columns, assay plates, and purification kits. Whether in the lab, clinical settings, or other industries.

Talk with a Material Science Expert

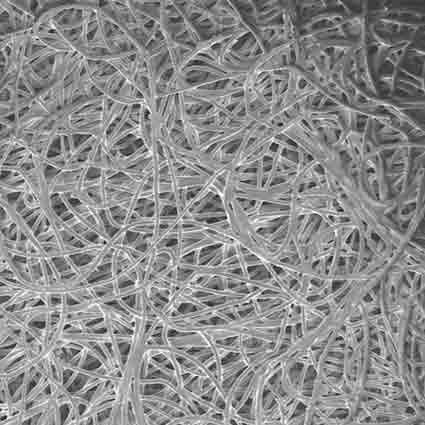

Manufacturing process for glass fiber filters

Made in the USA, Porex glass fiber media production involves advanced techniques that transform pure borosilicate glass into high-quality filtration material without using binders. The process starts with the glass fibers in a fluffy state, followed by a weak acid treatment. This process helps break down the glass fibers and ensures they are uniformly dispersed in the solution. Although the acid treatment may slightly etch the surface of the particles, it is necessary for achieving homogeneity. Finally, a rinsing step with the appropriate chemical can be added to produce fiber with different chemistries.

Options for customizing glass fiber

Register for Our On-Demand Webinar

Intro to Porous Fiber

Common applications for glass fiber

Filter

Glass fiber is versatile filtration media, proving effective as a pre-filter and in applications demanding high operating temperatures. Its adaptability makes it a reliable choice for various filtration needs, ensuring efficient performance in diverse conditions.

Wick

Demonstrating remarkable effectiveness in wicking, capillary forces enable fluid transfer with ease in numerous applications. This quality makes it a reliable choice for diverse scenarios where efficient fluid movement is essential.

Related Resources

Understanding Pore Size Distribution

In this video, learn how to measure the space between the particles and it’s effect on component performance.

Understanding Pore Volume

Explore the impact of pore volume to better understand its impact on your device’s functionality.

Your Partner in Innovation

Discover how Porex has been a partner in innovation for over 60 years in this video.

Electrochemical Gas Sensor Components Brochure

Discover innovative porous polymer solutions and components to increase the performance of electrochemical gas sensors.