Porous polymer geometric expertise for any design

Porex provides a wide range of material solutions, including both standard and customizable geometries, such as porous plastic sheets, rods, and tubes. These porous polymer components offer exceptional properties, including impressive strength, durability, chemical resistance, and resiliency.

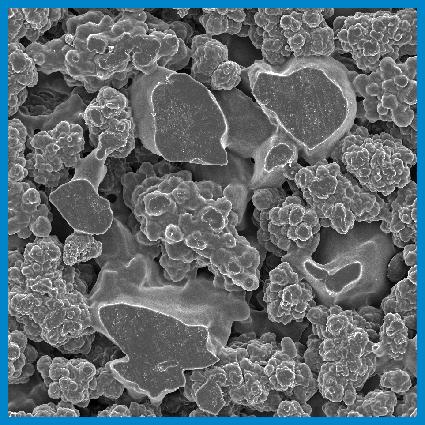

Our approach prioritizes design adaptability to meet diverse application needs, whether it involves filtration, absorption, applicator, venting, diffusing, or wicking. Unlike traditional injection molding, our manufacturing method utilizes controlled heat and pressure to create a connected pore structure, which allows for precise control over particle flow within your device. With Porex, you can explore standard and custom geometries, focusing on functional benefits to enhance your design.

Options for porous polymers

Geometric options for porous polymers

Porous plastics offer an exceptional advantage with their adaptability to a wide range of geometric requirements. From porous plastic sheets and rolls to more custom, intricate 3D shapes, these provide immense flexibility in your design and manufacturing endeavors. The various geometric options span a broad spectrum, encompassing standard sheets or rolls, rods, tubes, nibs (for writing instruments), 2D plugs, and simple and complex 3D shapes.

At Porex, we embrace innovation as your partner and engineers collaborate with you to understand your unique manufacturing process and design goals, ensuring that the material size, shape, and dimensions perfectly align with your vision.

Converting and assembly solutions

Porex offers comprehensive solutions for converting and assembly processes to meet your specific needs. Whether it’s porous plastic sheets, rods, tubes, or converting technologies, including die-cutting with tools, digital knife cutting, and rotary die-cutting, enabling the precise transformation of raw materials into custom-designed components. Whether you require cost-effective options, high precision, or flexibility for rapid prototyping, our techniques accommodate a wide range of demands.

For assembly, options include ultrasonic welding and overmolding for robust bonds or opt for pressure-sensitive adhesives (PSAs) for reliable, adhesive-based assembly. Thermal and ultrasonic welding offers a mechanical bond, while press fitting is effective for creating seals. Our material science experts can assist you in selecting the most suitable method based on operating conditions, environmental factors, and your project’s specific requirements.

Porous Plastic Sheets, Tubes, and Rods

Explore Porex’s diverse offerings of porous plastic sheets, tubes, and rods. From customizable sheet options to versatile tubes and rods designed for wicking applications, Porex has the solutions to elevate your projects.

Porous Plastic Sheets

Porex offers a range of standard porous plastic sheet options that can be further customized using our diverse converting methods. Our sheets are adaptable for various applications and can be converted by die-cutting, digital knife cutting, and rotary die-cutting.

Porous Plastic Tube

With a selection of standard porous plastic tube solutions, ready for further customization in pore size, pore volume, and sizing, We provide you the freedom to pick the best material for your specific application.

Porous Plastic Rods

Porous plastic rods from Porex are available in various standard sizes, ensuring versatility for your specific needs and wicking applications with micron size options ranging from 15 to 75 microns, ensuring precise control over capabilities.