Innovative Positioning Foam Provides the Protection Doctors Need, Comfort Patients Want

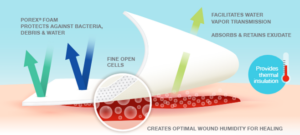

Engineered using a two-step manufacturing process, Porex’s open-cell foam technology is developed using proprietary blends of raw materials through a clean polyurethane foaming process without the use of catalysts. By leveraging different formulations of materials, Porex can offer wide-ranging densities, porosities, and levels of softness to meet specific medical applications. From super soft foam for wearables to slow recovery foam for cranial and body protectors, our design engineers will work with you to select and design the foam that meets your needs.

Register for our On-Demand Webinar

Redefining the Capabilities of foam with Open-Cell Technology

Applications

Medical Care

Porex’s polyurethane foam can support a broad range of medical care applications including cranial and spinal protection, hip and extremity protection, head and body positioning, posterior cushioning, wheelchair seating, splint padding, patient handling, surgery securement, face masks and strips, as well as wearable reinforcement panels among others.

Related Resources

Advanced Wound Care Foam Brochure

Explore our Advanced Wound Care Brochure and Our diverse line of foams features wide-ranging

physical properties and options for enhancement with additives, adhesives, and coatings.

Chemical Compatibility Chart – Polymer Comparison

Access our comprehensive chemical compatibility chart, a valuable resource for comparing different polymers based on their chemical compatibility.

Porex Medical Solutions – Brochure

Discover the range of Porex medical-grade porous materials and filters designed for various applications in the medical field, ensuring optimal performance and reliability.

Life Science Applications Media and Filters Brochure

Explore Porex’s range of media and filters for life science applications including liquid handling, chromatography, SPE, separation, affinity, and DNA/RNA purification and extraction.