Protect and enhance sensor performance with cutting-edge technology

Manufacturers around the world trust Porex for cutting-edge technology that outperforms the competition. POREX® materials maximize performance for many sensor applications, including gas absorption, venting, diffusion and electrolyte holding and wicking.

Our customizable solutions for sensor manufacturers can be tailored to specific applications or devices and seamlessly integrated with many manufacturing processes.

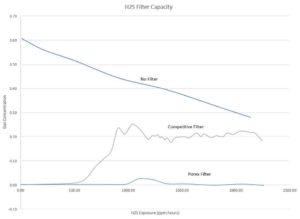

Gas Absorption Filters

Filters customized with gas-absorbing material from Porex are designed to target specific gases that may cause a sensor to have a false reading or cause premature degradation of the cell itself.

Expertly and individually designed for your sensor devices, our gas-absorbing filters:

Options for customizing gas sensor absorption filters

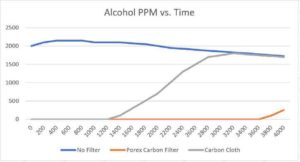

Protection Vents and Diffusion Layer

Equalize pressure and repel contaminants

POREX Virtek® IP-rated PTFE vents are designed to provide fast gas diffusion, while repelling dust, water and other contaminants. Specifically designed for electronic devices, our protection vents:

Options for customizing sensor protection vents and diffusion layer

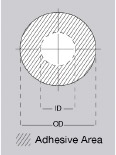

Electrolyte Reservoirs and Wicks

Reservoirs and wicks are needed to retain and deliver an electrochemical system’s electrolyte to facilitate the chemical reaction. POREX® fiber and foam media can be used for reservoirs, general wicking and supporting fluids within electronics and sensors.

Engineered for optimal capacity and directional flow, our electrolyte reservoirs and wicks:

- Minimize inhalation and skin hazards – Made from safe-to-use PP or PE, our materials eliminate the need for glass wool, which can cause skin irritations and health issues when inhaled.

- Meet your application specifications – Product fluid retention, density and flow orientation can be tailored to meet your specific application needs.

Related Resources

Electrochemical Gas Sensor Components Brochure

Discover innovative porous polymer solutions and components to increase the performance of electrochemical gas sensors.

Improving Accuracy in Electrochemical Gas Sensors Case Study

See how our Porex engineering team developed a solution to address the challenges encountered in gas detection within industrial settings.

Secrets to Improving the Efficiency of Your Gas Sensors Webinar

Discover how to enhance gas sensor performance in our webinar. Learn to extend sensor lifespan, lower production costs, improve accuracy, and increase efficiency.

Porex LED Reflectors

Explore reflectivity media for LED reflectors. Learn more about how Porex Virtek PTFE membrane can maximize UV for disinfection applications with its outstanding UV reflectivity