What is the function of wicking media?

Wicking is simply fluid transfer by means of capillary action. Capillary action is the process through which liquid flows in a narrow, porous wicking media without the assistance of, or even in opposition to, external forces like gravity. This process can be seen in everyday items – such as markers, inkjet printers, and at-home air fragrance systems that transfer and release liquids from a reservoir in a controlled manner – as well as diagnostic sample collection devices, lateral flow assay tests, and nebulizer reservoirs.

Porex has been designing and developing fluid transfer and management systems utilizing porous fiber materials for over 50 years. In addition to our material science and component design expertise, we offer a wide variety of base material options – from thermoplastic polymers to synthetic fibers. Our wicking media is designed with open-cell pore structures that control liquid volume capacity and fluid transfer rates, and our experts have the ability to alter the surface energy of the materials to further enhance media capillarity. Our products are custom engineered to optimize fluid transfer based on specific end-use product and applicational requirements.

Talk with a Material Science Expert

Webinar

In this webinar preview explore wicking media solutions as we discuss:

- The details of the wicking process

- The difference between hydrophobic and hydrophilic wicking

- The typical problems that are solved with wicking

You’ll learn about the life sciences and consumer applications that require effective wicking, the different porous materials that make wicking possible, and so much more.

How wicking media works with porous polymers

Fluid flow is governed by surface energy and capillary forces. Surface energy is the disruption of intermolecular bonds that occur when a surface is created, and there is a difference in energy between the substrate and liquid. It is used to determine if a material is hydrophobic or hydrophilic by measuring the contact angle. For wicking to occur, a material must be hydrophilic with high surface energy, meaning it is easy to wet-out and can support the occurrence of capillary forces. The capillary action of a wicking process can allow for the movement of fluids in tight spaces without – or sometimes against – the force of gravity. The height that a liquid will travel – or wick – is inversely proportional to the pore size. A smaller pore size results in a higher wicking height and vice versa.

Why do pore size and flow matter?

Learn more in our new technical article

Watch how porous polymers enable wicking

Design challenges solved by wicking media

- Moving a bodily fluid sample through an in-vitro diagnostic test system

- Transferring ink from a coloring marker reservoir to the nib (tip) for writing onto a surface

- Moving liquid to a collection point

- Collecting a diagnostic test sample such as saliva or urine

- Sucking up a defined quantity of formulas or chemicals, such as makeup, so that it can be applied to a surface

- Drawing oil or water through a reed wick for a home air freshener system

Related Technologies

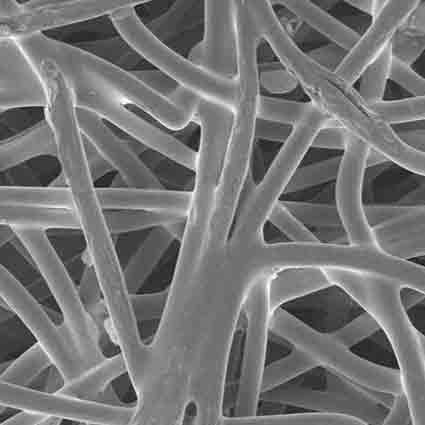

Porous Fiber

Porous fibers consist of bonded fibrous strands which create two-dimensional cross-sections that can be extruded to create three-dimensional shapes.

Register for our On-Demand Webinar

Using Porous Plastics for Wicking