What is the function of porous filtration media?

Filtration is the process of separating a solid or a liquid from a mixture via a porous filtration media. It is one of the most critical functionalities of a porous filter, as seen in a variety of applications all around us. This includes at-home water filters that can remove lead and other harmful heavy metals from drinking water, automotive water separation media that ensures oil and fuel integrity, and protective filters in medical applications that can prevent contamination.

Porex porous filters and separation media materials have been used for decades in the most demanding filtration and separation applications. Offering both surface and depth filtration functionality, our porous structures are comprised of an omnidirectional, interconnecting matrix, which can be optimized for filtration efficiencies to match your application’s requirements. Additionally, our porous filtration media may be surface-modified or include additives to enhance functionality for improved performance, durability, and design flexibility.

Talk with a Material Science Expert

Filtration Webinar

In this webinar preview, explore filtration media solutions as we discuss:

- How filtration works

- The difference between a physical filter and a chemical filter

- The typical problems that are solved with filtration media

You’ll learn about the filtration spectrum, how to create an effective filter, and so much more.

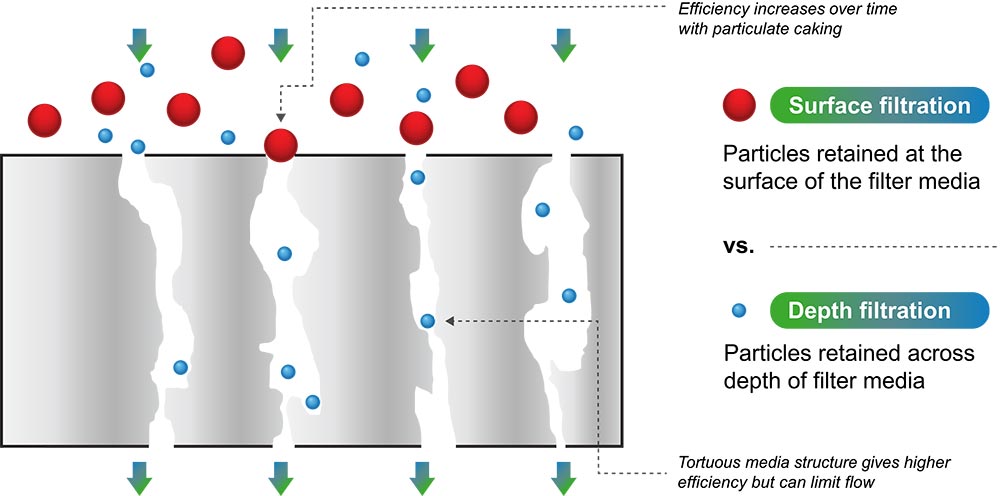

How filtration media works in porous filters

Filtration can be achieved physically, chemically, or through a biological process. The concept of a physical porous filter is simple – it is designed to allow fluids (filtrates) to pass through while solids (oversized) are retained. A simple kitchen sink strainer is a perfect example, as water passes through while food that needs to be disposed of in the garbage becomes trapped. Pore size, or simply the size at which the largest particle can pass, and tortuosity, the degree of complexity of the porous paths within a media, are important to consider when designing your filtration media. When particles are retained at the surface, it is known as surface filtration, whereas when they are retained within the tortuous path of the media structure, it is considered depth filtration. It is important to note that porous polymer filtration media can be designed using a combination of these methods.

Chemical filtration is primarily achieved through the process of adsorption, a surface phenomenon where ions, atoms, and molecules of a substance (liquid, solid, or gas) are preferentially retained on the surface of an absorbent (such as carbon). Chemical filters depend on pore size, surface area, and surface energy of adsorbents to function properly.

Design challenges solved by porous filtration media

- Separating and removing impurities from drinking water

- Removing unwanted substances from a test stream to allow for accurate analysis

- Preventing unwanted gases from escaping into the home, office, or industrial environment

- Filtering sediment out but allowing for water to pass

- Allowing for sound to be separated from wind background noise

- Keeping engines from being contaminated by particles in the fuel stream

- Protecting nasal drug delivery devices from mechanical obstruction

Related Technologies

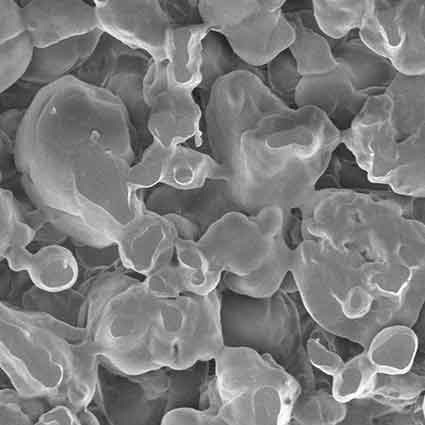

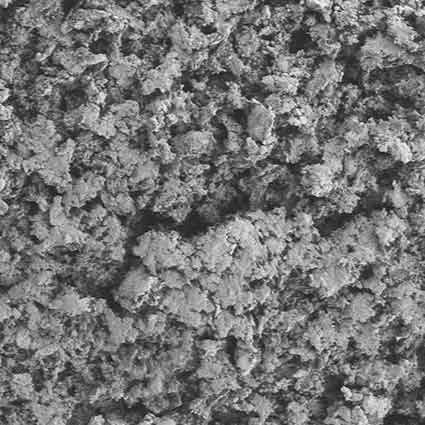

Sintered Porous Plastics

Sintered porous plastics are created using a combination of heat and pressure to bond the materials together.

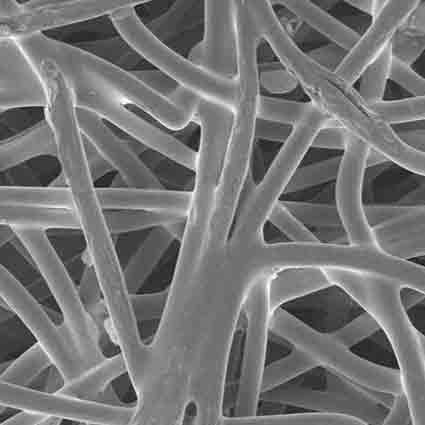

Porous Fiber

Porous fibers consist of bonded fibrous strands which create two-dimensional cross-sections that can be extruded to create three-dimensional shapes.

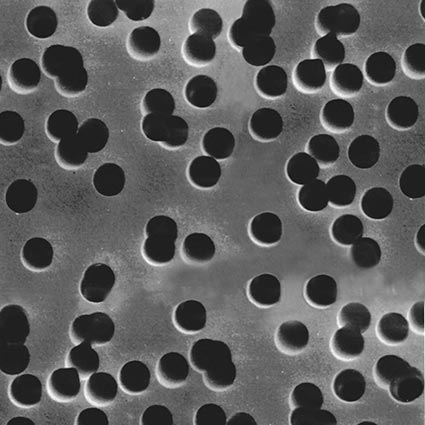

Track-Etched Membranes

Oxyphen track-etched membrane technology features the most precise control over pore size and pore density of any membrane on the market.

Sintered PTFE Membranes

Sintered PTFE membranes are naturally hydrophobic and robust enough to be used without support.

Register for our On-Demand Webinar

Using Porous Plastics for Filtration