Increase durability and performance of fueling systems

Engineers who design fuel systems and power tools choose POREX® porous material solutions for filtering and venting of fuel and particulate in home heating, small engines, marine engines and power tools.

As a durable solution for optimal performance, our innovative products:

- Meet hydrocarbon emission requirements demanded to reduce emissions and improve air quality.

- Ensure optimal performance with long-lasting and durable design.

- Increase filtration efficiency with engineered structure that optimizes air flow rates.

Oil Filters for Home Heating Systems

Improve the efficiency of home heating systems

Fuel Vents for Marine

Reduce hydrocarbon emissions with oleophobic marine vents

Fuel Filters and Vents for Small Engines

Increase power and performance of small engines

Dust Canisters for Power Tools

Keeping power tools clean and working hard

Oil Filters for Home Heating Systems

Improve the efficiency of home heating systems

Engineered for use in home heating systems, POREX® oil filters are designed in various shapes, sizes, and a range of filtration efficiencies to provide high oil-flow rates. With an insert-molded polypropylene (PP) base that is threaded for ease of cartridge connection, our filters are cost-effective and easy to replace.

Specifically designed for home heating efficiency, our filters:

- Offer high flow rates to optimize filtration efficiency.

- Save replacement time – Threaded base makes it easier to connect cartridge when replacing spent filters.

- Improve performance of home heating systems – Designs can be customized with multiple shapes, sizes and filtration efficiency options.

Fuel Vents for Marine

Reduce hydrocarbon emissions with oleophobic marine vents

Manufacturers of marine and small engines around the world trust POREX® oleophobic vents as a key system component to comply with EPA standards for reducing hydrocarbon emissions. With its functional design, these oleophobic vents will not absorb fuel or allow the passage of fuel through the vent, but will allow for optimal air-flow exchange between the fuel tank and the hydrocarbon absorbing system.

Our oleophobic vents:

- Provide optimal air-flow exchange – Deliver optimal exchange between the fuel tank and the hydrocarbon absorbing system.

- Prevent fuel escape from the tank

- Do not absorb fuel through the vent for tighter control

Features

- Help manufacturers comply with EPA standards for reduced hydrocarbon emissions

- Oleophobic and won’t absorb fuel or let fuel past the vent

- Allow for optimal air-flow exchange between the fuel tank and the hydrocarbon absorbing system

- Free of PFOA: Compliant with (EC) 1907/2006 REACH / Regulation (EU) 2019/1021 POP

Materials Offered

- PTFE membrane and molded components

Formats Available

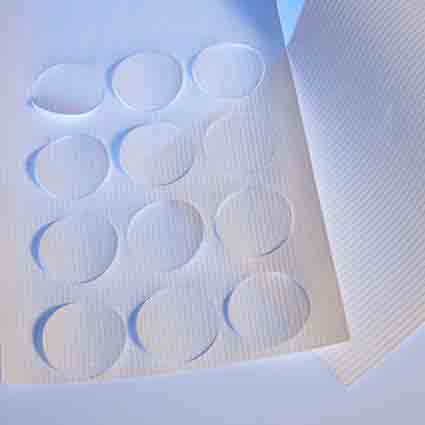

- Rolls or die cut disks

- Oleophobic

Porex Virtek – Automotive / oleophobic product range (hydrophobic & oleophobic)

| Item Number | IP Rating † | WEP* mbar (Typical) | Typical Airflow l/hr/cm² @70mbar | Filtration Efficiency** >99.99% | Thickness mm | Max Operating Temp °C | Salt Fog$ |

|---|---|---|---|---|---|---|---|

| PMA10‡ | 64,67 | 380 | 70 | 0.4 µ | 0.18 | 260 | No pen. |

| PMA15‡ | 65,67,68 | 520 | 34 | 0.1 µ | 0.25 | 260 | No pen. |

| PMA20‡ | 65,66,67,68 | 1000 | 5 | 0.1 µ | 0.19 | 260 | No pen. |

Porex Virtek – General Puropse Venting product range (hydrophobic)

| PMV10 | 64,67 | 270 | 125 | 0.5µ | 0.13 | 260 | No Pen. |

| PMV10L*** | 64,67 | 270 | 85 | 0.5µ | 0.3 | 100 | No Pen. |

| PMV15 | 64,67 | 380 | 70 | 0.4µ | 0.18 | 260 | No Pen. |

| PMV15T‡ | 64,67 | 380 | 70 | 0.4µ | 0.18 | 260 | No Pen. |

| PMV20 | 64,65,68 | 520 | 34 | 0.1µ | 0.25 | 260 | No Pen. |

| PMV25 | 65,67,68 | 750 | 15 | 0.2µ | 0.1 | No Pen. | |

| PMV27 | 65,66,67,68 | 1000 | 5 | 0.1µ | 0.19 | 260 | No Pen. |

| PMV30 | 65,66,67,68 | 1000 | 4.5 | 0.1µ | 0.25 | 260 | No Pen. |

*WEP = Water Entry Pressure

** According to IEST RP-CC007.2 2009

$ASTM B117-11 test method

***Laminated polyolefin mesh backing

‡ Oleophobic, AATCC TM 118 – Grade 8

Moisture Vapor Transmission Rate approx. 900g/m2/day. ASTM E96-16 water escaped from sealed cup @ 23±2°C, 50±10%rH chamber.

Properties are typical and not meant for specifications. Selected options and adhesives may affect properties

RoHS, WEEE, REACH Compliant (PFOA Free)

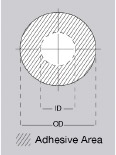

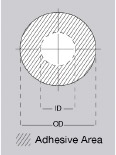

STOCK PRODUCT OFFERING BY MATERIAL SERIES – POREX Virtek® ADHESIVE DISCS

| Dimensions | ||||

|---|---|---|---|---|

| OD x ID (mm)* | PMV10L | PMV15 | PMV20 | PMV30 |

| 7.0 x 3.0 (N) | PMV10LN | PMV15N | PMV20N | PMV30N |

| 10.0 x 6.0 (P) | PMV10LP | PMV15P | PMV20P | PMV27P** |

| 12.7 x 7.1 (W) | PMV10LW | PMV15W | PMV20W | PMV30W |

| 20.0 x 13.0 (C) | PMV10LC | PMV15C | PMV20C | PMV30C |

| 12.7 x 7.1 (W) | PMV15WH# | |||

| 12.7 x 7.1 (W) | PMV15TWH## |

*1000 discs/roll

**PMV27 will become the new standard offering – other sizes will follow

# With high temperature adhesive (good to 150 °C )

## Oleophobic Treated and high temperature adhesive (good to 150 °C )

N, P, W & C are size codes.

Many other standard and custom sizes available. Contact Porex for more information

Related Resources:![]() Demonstration video: How Porex Virtek PTFE Vents Work

Demonstration video: How Porex Virtek PTFE Vents Work

Fuel Filters and Vents for Small Engines

Increase power and performance of small engines

Highly designed filters and vents are critical for a small engine’s performance. Our filters and vents work to help small engines deliver more powerful performance.

Optimized for small engines, our filters and vents:

- Increase engine durability– Filters are proven to withstand the harsh fuel environment

- Enhance performance– Filters have self-orienting ability so that performance is consistent no matter the position of the power tool.

- Provide optimal air-flow exchange bydelivering optimal exchange between the fuel tank and the atmosphere.

Features

- Filters are self-orienting no matter the position of the power tool

- Oleophobic and won’t absorb fuel or let fuel past the vent

- Allow for optimal air-flow exchange between the fuel tank and the hydrocarbon absorbing system

Materials Offered

- Filters – Advanced porous materials – PE or PP

- Vents – PTFE membrane and molded components

Formats Available

- PE or PP – molded shapes

- PTFE – Rolls or die cut disks, oleophobic options

Porex Virtek – Automotive / oleophobic product range (hydrophobic & oleophobic)

| Item Number | IP Rating † | WEP* mbar (Typical) | Typical Airflow l/hr/cm² @70mbar | Filtration Efficiency** >99.99% | Thickness mm | Max Operating Temp °C | Salt Fog$ |

|---|---|---|---|---|---|---|---|

| PMA10‡ | 64,67 | 380 | 70 | 0.4 µ | 0.18 | 260 | No pen. |

| PMA15‡ | 65,67,68 | 520 | 34 | 0.1 µ | 0.25 | 260 | No pen. |

| PMA20‡ | 65,66,67,68 | 1000 | 5 | 0.1 µ | 0.19 | 260 | No pen. |

Porex Virtek – General Puropse Venting product range (hydrophobic)

| PMV10 | 64,67 | 270 | 125 | 0.5µ | 0.13 | 260 | No Pen. |

| PMV10L*** | 64,67 | 270 | 85 | 0.5µ | 0.3 | 100 | No Pen. |

| PMV15 | 64,67 | 380 | 70 | 0.4µ | 0.18 | 260 | No Pen. |

| PMV15T‡ | 64,67 | 380 | 70 | 0.4µ | 0.18 | 260 | No Pen. |

| PMV20 | 64,65,68 | 520 | 34 | 0.1µ | 0.25 | 260 | No Pen. |

| PMV25 | 65,67,68 | 750 | 15 | 0.2µ | 0.1 | No Pen. | |

| PMV27 | 65,66,67,68 | 1000 | 5 | 0.1µ | 0.19 | 260 | No Pen. |

| PMV30 | 65,66,67,68 | 1000 | 4.5 | 0.1µ | 0.25 | 260 | No Pen. |

*WEP = Water Entry Pressure

** According to IEST RP-CC007.2 2009

$ASTM B117-11 test method

***Laminated polyolefin mesh backing

‡ Oleophobic, AATCC TM 118 – Grade 8

Moisture Vapor Transmission Rate approx. 900g/m2/day. ASTM E96-16 water escaped from sealed cup @ 23±2°C, 50±10%rH chamber.

Properties are typical and not meant for specifications. Selected options and adhesives may affect properties

RoHS, WEEE, REACH Compliant (PFOA Free)

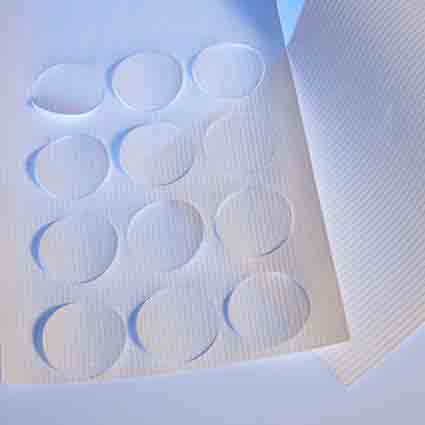

STOCK PRODUCT OFFERING BY MATERIAL SERIES – POREX Virtek® ADHESIVE DISCS

| Dimensions | ||||

|---|---|---|---|---|

| OD x ID (mm)* | PMV10L | PMV15 | PMV20 | PMV30 |

| 7.0 x 3.0 (N) | PMV10LN | PMV15N | PMV20N | PMV30N |

| 10.0 x 6.0 (P) | PMV10LP | PMV15P | PMV20P | PMV27P** |

| 12.7 x 7.1 (W) | PMV10LW | PMV15W | PMV20W | PMV30W |

| 20.0 x 13.0 (C) | PMV10LC | PMV15C | PMV20C | PMV30C |

| 12.7 x 7.1 (W) | PMV15WH# | |||

| 12.7 x 7.1 (W) | PMV15TWH## |

*1000 discs/roll

**PMV27 will become the new standard offering – other sizes will follow

# With high temperature adhesive (good to 150 °C )

## Oleophobic Treated and high temperature adhesive (good to 150 °C )

N, P, W & C are size codes.

Many other standard and custom sizes available. Contact Porex for more information

Related Resources:![]() Demonstration video: How Porex Virtek PTFE Vents Work

Demonstration video: How Porex Virtek PTFE Vents Work

Dust Canisters for Power Tools

Keeping power tools clean and working hard

Maximize efficiency of your power tools with POREX® dust canisters. Keeping the user and work environment free from hazardous dust discharge, our filters can be cleaned and reused for maximum life and cost effectiveness.

Specifically designed for power tools, our dust canisters:

- Reduce costs – Easy-to-clean canister can be reused.

- Improve safety – Keep user and environment free of hazardous dust discharge by capturing dust and particulates.

- Offer long-lasting, durable structure to maximize tool life.

Features

- Capture dust and particulate from power tool operation

- Cleanable and reusable

- Long lasting, durable construction

Materials Offered

- Advanced porous materials – PE

Formats Available

- 3D molded shape