Equalize container pressure to prevent distortion or damage with vents

Multiple complications can arise when industrial and consumer container products are processed, transported and stored. These products can become bloated, collapse or even explode due to unequal pressure. Container manufacturers trust POREX® vents to enable their containers to “breathe,” thereby equalizing pressure within the container to prevent distortion or damage.

Vents engineered to exact closure specifications that:

- Feature POREX Virtek® material that enables a constant controlled vent rate while retaining and safeguarding container contents.

- Are effective with a wide variety of contained materials including solvent or water-based solutions; granular or powder chemicals; foods and beverages; and low surface tension fluids such as oils, detergents and surfactants.

- Ensure safety with gas transfer capability in both directions based on pressure equalization needs.

Cap and Closure Vents for Industrial Containers

Assure

container integrity during transportation and storage

Vents for Household Cleaning Supplies

Prevent leakage of household cleaning products

Cap and Closure Vents for Industrial Containers

Assure container integrity during transportation and storage

POREX Virtek vent material addresses industrial packaging requirements to allow container integrity throughout the transportation and storage process. Container manufacturers value our weldable, breathable, leak-resistant material as a solution for venting many types of industrial and consumer containers.

Designed for use with solvent or water-based solutions, granular chemicals, or for use with low surface tension fluids such as oils, detergents and surfactants, our cap and closure vents:

- Protect container integrity – Prevent pressure change complications through the transportation and storage process with a breathable, leak-free solution.

- Secure containers – POREX Virtek material has excellent strength properties, which enable weldable or press-fit assembly, providing manufacturing flexibility and convenience.

- Maximize container performance– Engineered high airflow provides consistent pressure equalization with superior leak resistance.

| Material Performance | ||||

|---|---|---|---|---|

| Product # | Material | Water Intrusion Pressure (mbar) -Typical- |

Airflow (l/hr/cm2 @ 10 mbar) -Typical- |

Thickness (mm) |

| 96193 | PE | 150 | 14 | 0.7 |

| 9619 | PE | 150 | 10 | 1.5 |

| 9948 | PE | 180 | 7 | 3.1 |

| PM3V | PTFE | 400 | 9 | 0.18 |

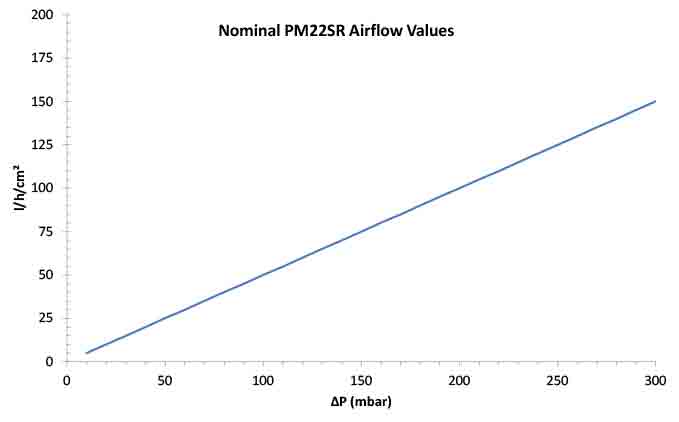

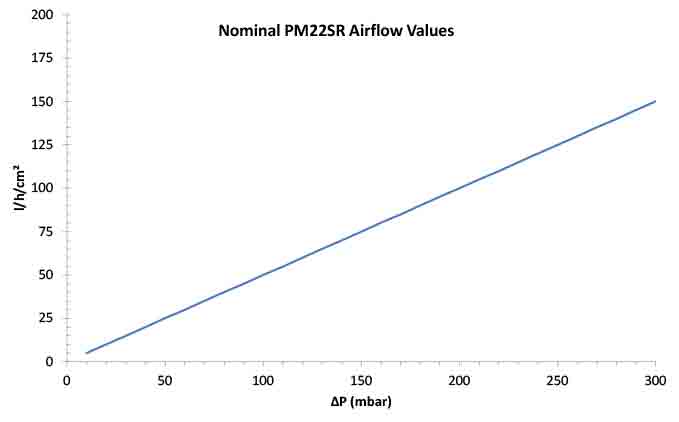

| PM22S | PTFE | 525 | 8 | 0.25 |

| PM6M | PTFE | 770 | 3 | 0.1 |

| Material Properties | |||

|---|---|---|---|

| Properties | PTFE* | PP | PE |

| Heat Resistance (softening point) | 260°C | 172°C | 130°C |

| Heat Resistance (melting point) | >260°C | 193°C | 160°C |

| Hydrophobicity | Excellent | Good | Good |

| Oleophobicity | Available upon request | N/A | N/A |

| Geometry | Sheet/vent plug/disc | Sheet/vent plug | Sheet/vent plug |

|

*PTFE compliant with UN Dangerous Goods Packaging Performance Standard: Part 6.1.5 of Chapter 6.1 of the United Nations Model Regulations, 15th Edition |

|||

| POREX® Cap Closure Vents | |

| Product | Description |

|---|---|

| PM22SR | 330mm Roll |

| PM22STR | Oleo 330mm Roll |

| PM22SDC | 16mm Disc |

| PM22STDC | Oleo 16mm Disc |

Related Resources:

![]() Datasheet: Vents for Cap Closures and Liners

Datasheet: Vents for Cap Closures and Liners

![]() Datasheet: POREX Virtek PTFE Vents for Cap Closures

Datasheet: POREX Virtek PTFE Vents for Cap Closures

Vents for Household Cleaning Supplies

Prevent leakage of household cleaning products

Household cleaning product manufacturers know the risks associated with unwanted container leakage and contact with skin. To increase security of these products, our POREX Virtek vent material protects product container integrity with breathable pressure equalization while minimizing the risk of unwanted leakage.

Providing a safe, reliable solution, our vents:

- Maintain package integrity, providing a breathable, leak-resistant vent solution to protect contents from leaking.

- Enable secure and convenient assembly with both weldable and press-fit assembly capability.

- Protect consumers with leak-resistant venting for everyday cleaning supplies.

| Material Performance | ||||

|---|---|---|---|---|

| Product # | Material | Water Intrusion Pressure (mbar) -Typical- |

Airflow (l/hr/cm2 @ 10 mbar) -Typical- |

Thickness (mm) |

| 96193 | PE | 150 | 14 | 0.7 |

| 9619 | PE | 150 | 10 | 1.5 |

| 9948 | PE | 180 | 7 | 3.1 |

| PM3V | PTFE | 400 | 9 | 0.18 |

| PM22S | PTFE | 525 | 8 | 0.25 |

| PM6M | PTFE | 770 | 3 | 0.1 |

| Material Properties | |||

|---|---|---|---|

| Properties | PTFE* | PP | PE |

| Heat Resistance (softening point) | 260°C | 172°C | 130°C |

| Heat Resistance (melting point) | >260°C | 193°C | 160°C |

| Hydrophobicity | Excellent | Good | Good |

| Oleophobicity | Available upon request | N/A | N/A |

| Geometry | Sheet/vent plug/disc | Sheet/vent plug | Sheet/vent plug |

|

*PTFE compliant with UN Dangerous Goods Packaging Performance Standard: Part 6.1.5 of Chapter 6.1 of the United Nations Model Regulations, 15th Edition |

|||

| POREX® Cap Closure Vents | |

| Product | Description |

|---|---|

| PM22SR | 330mm Roll |

| PM22STR | Oleo 330mm Roll |

| PM22SDC | 16mm Disc |

| PM22STDC | Oleo 16mm Disc |

Related Resources:

![]() Datasheet: Vents for Cap Closures and Liners

Datasheet: Vents for Cap Closures and Liners

![]() Datasheet: POREX Virtek PTFE Vents for Cap Closures

Datasheet: POREX Virtek PTFE Vents for Cap Closures